DESCRIPTION

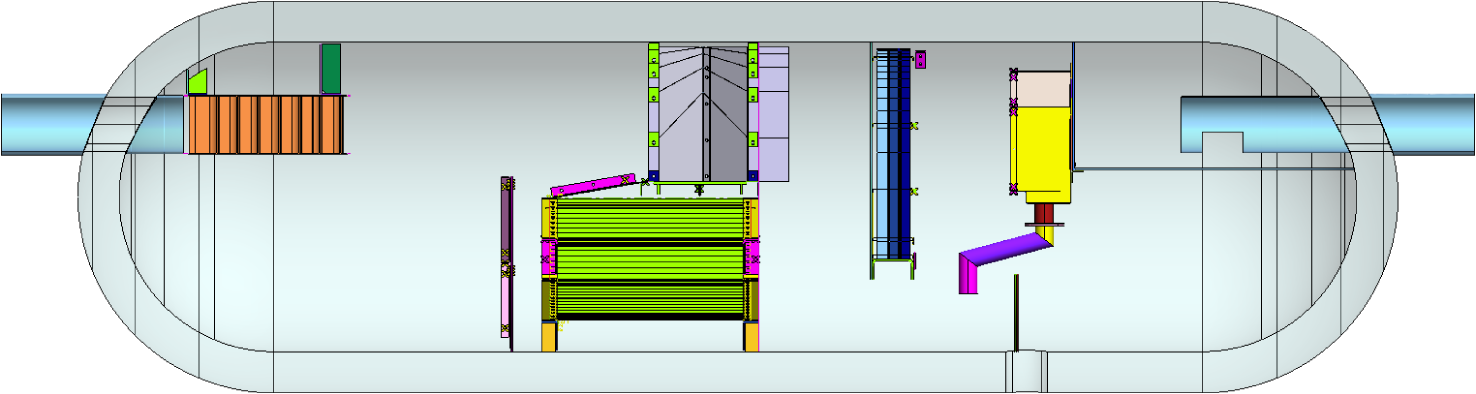

Wire mesh demisters are widely used when is required to separate liquid droplets from a gas flowrate.

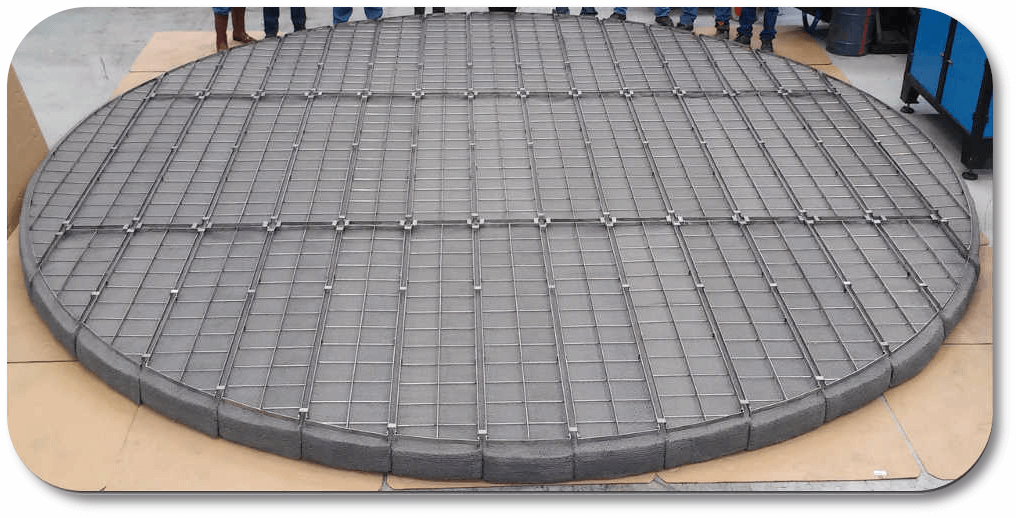

This kind of separators are made by an alveolar structure of wire mesh obtained by the superposition of different layers of tubular sock. This sock is woven with very thin wires (usually with a diameter smaller than 0.3 mm) which allows a structure with high free volume (usually > 95%), a wide active surface with a low density of the mesh for material and cost savings.

Wire mesh separators are used for example:

- to purify gasses;

- to eliminate liquids that could damage the production processes;

- to prevent problems to the plant structures;

- to prevent emissions dangerous for the environment;

- to recover expensive liquids

ADVANTAGIES

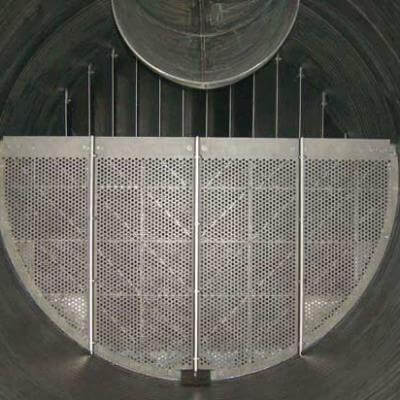

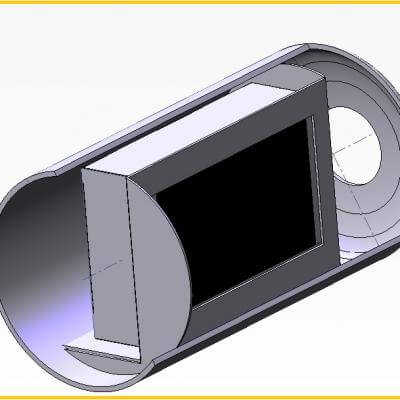

- Easy installation and moving through manholes and small spaces.

- High efficiency of the separation process.

- Low pressure drop.

- Reduction of the vessel dimensions with lower working costs.

- Lower costs in comparison with other separation methods.

ACCESSORIES

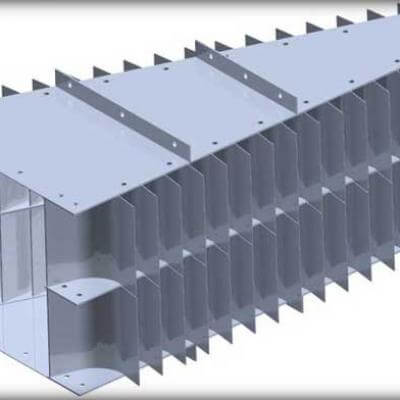

Wire mesh demisters are often supplied with accessories like boxes, extractors and fixing systems with every kind of round, tube, sheet or other profile. Most common types are:

- Support grates used to contain the mesh pad.

- Containment meshes usually used to contain the wire mesh in the support grates.

- Elements for fixing systems like: L bolts, J bolts, fixing wire.

- Superficial treatment: every welded material can be treated with a passivation process to eliminate all welding residue and avoid a corrosive effect due to an aggressive environment.