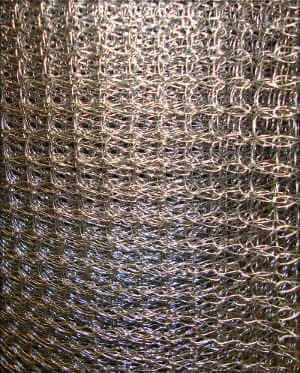

We can produce crimped wire meshes with different thickness or, when required, flat wire mesh. In both cases the width of our wire meshes is usually between 50mm and 600mm.

APPLICATIONS

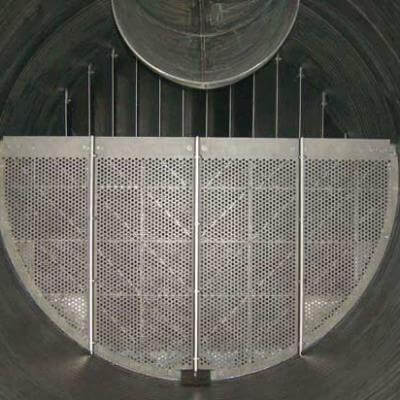

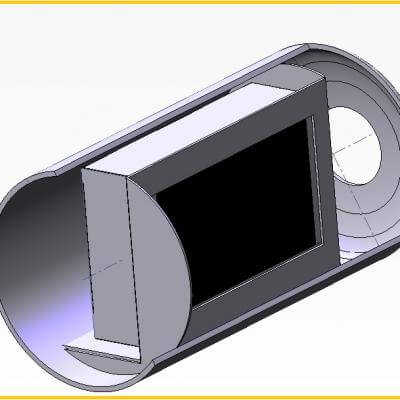

Knitted metallic wire mesh is the raw material used to produce wire mesh separators but it is also used in many different industrial applications to manufacture:

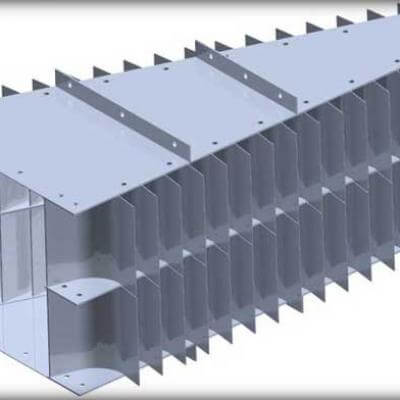

- full metallic anti-vibration dampers

- air treatment filters

- automotive components like filters, anti-vibrations, separator rings, silencers etc.

- thermal insulators

- anti-intrusion and anti-vandalism elements

- cleaning of mechanical components

- architecture and design components