1 - VANE PACK WITH MESH PAD AGGLOMERATOR

When:

- the dimension of the droplets is too small to be intercepted by the vanes

- the flow speed is too high for a normal wire mesh demister and it is not possible to retain the droplets which are torn over the mesh

- the required separation efficiency is very high for a vane pack

- the diameter of the vessel is too small to install a properly sized wire mesh demister

In this particular cases a wire mesh agglomerator must be applied before the window of the vane pack. As shown in the scheme below, the droplets, passing through the agglomerator, increase their dimension reaching the vane pack with the correct speed and diameter.

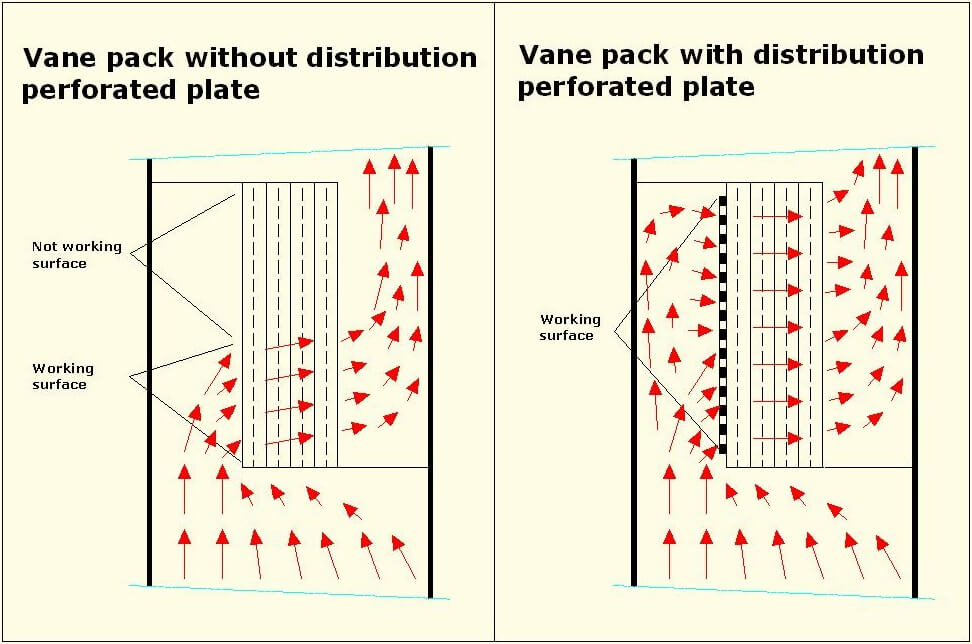

2 - VANE PACK WITH DISTRIBUTION PERFORATED SHEET

When the diameter of the vessel is too small to allow a correct distribution of the flow, there is the risk that the gas passes through only a fraction of the available area of the vane pack window.

This bad distribution of the gas flow causes two problems:

- an excessive speed of the gas flow through the vane pack

- a lower efficiency of the process because many droplets captured by the vanes can be torn over pack due to the too much high speed.

The problem can be solved applying a perforated distribution sheet that forces the distribution of the flow all over the available area of the vane pack window (see the scheme below)

Left: a sample of the phase of mounting of the wire mesh agglomerator on a vane pack for horizontal vessels

Right: a vane pack with distribution plate designed for separation in small vessels