SIZING OF A WIRE MESH DEMISTER

As known, wire mesh demisters can supply a high degree of separation (it is common to separate droplets with a diameter of 3 microns) with low pressure drop. To achieve the best performance, however, a proper sizing of the separators is of the utmost importance. With AFP ProCalcDem, our analytical method of calculation, we supply our customers with two different services according to the process conditions and fluids characteristics:

1 - cheking of an existing separator: the customer supplies us the process datasheet and the separator features. With these data our technical office checks the efficiency and pressure drop of the process and the dimensions of the existing separator.

2 - sizing of a new separator: according to the process datasheet, AFP Tech defines the type and the dimensions of the separator to achieve the requested efficiency and pressure drop.

After our calculation, we can suggest if it is necessary a replacement of the separators and of the vessel. Moreover we can supply a calculation report with the process efficiency and the pressure drop at the process conditions.

VANE PACK SIMULATION

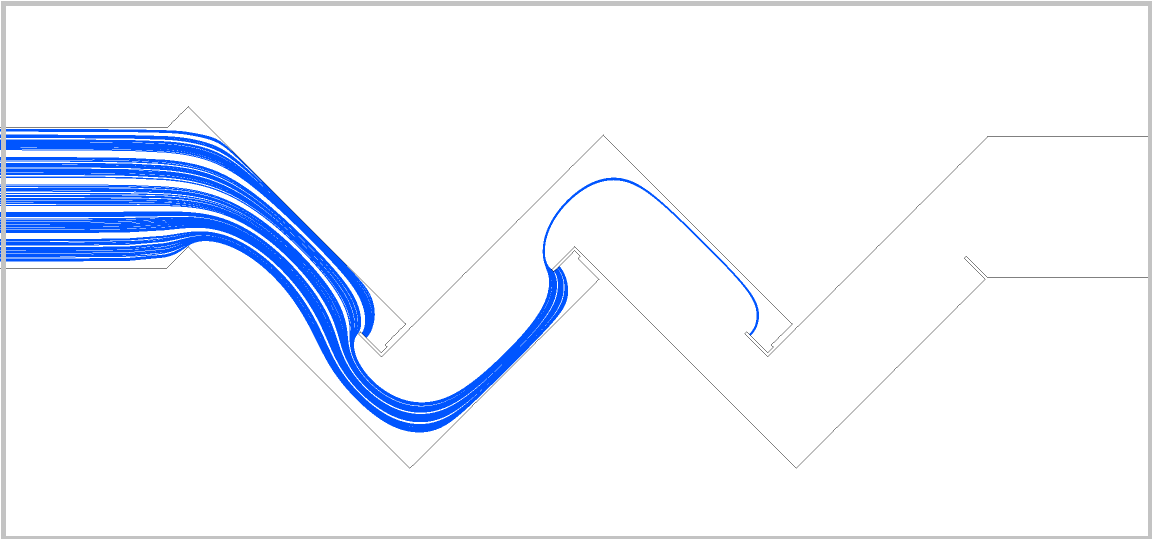

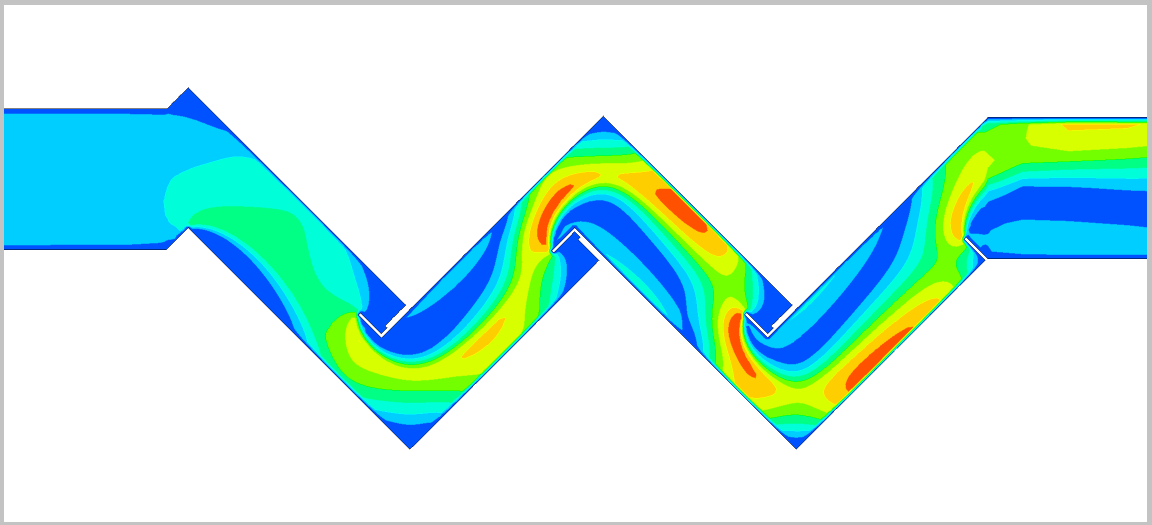

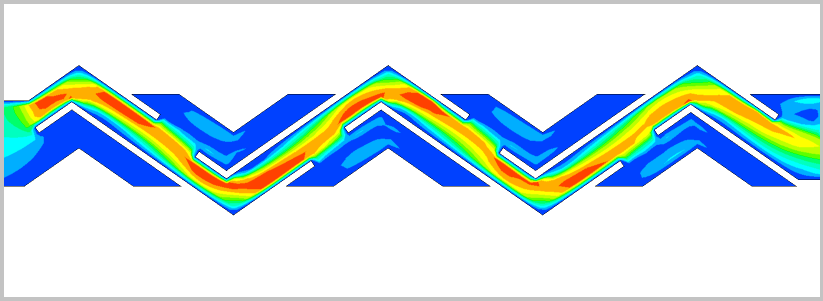

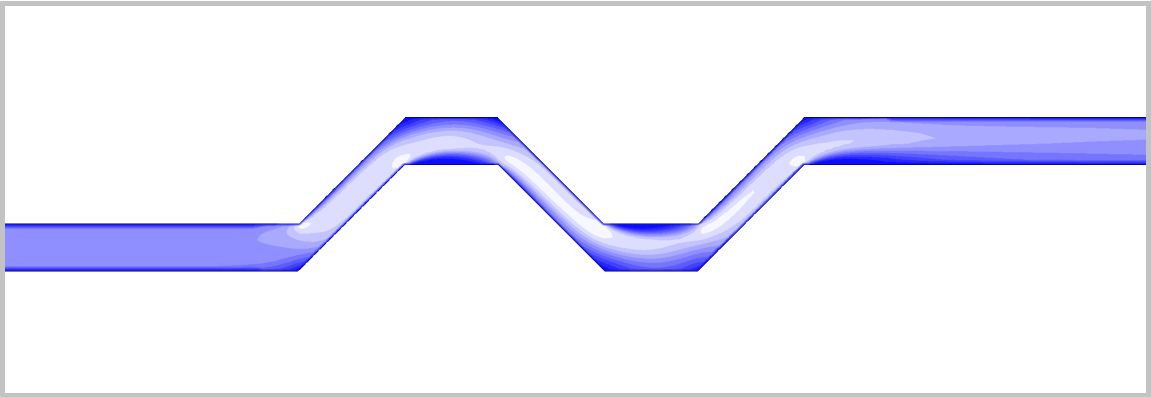

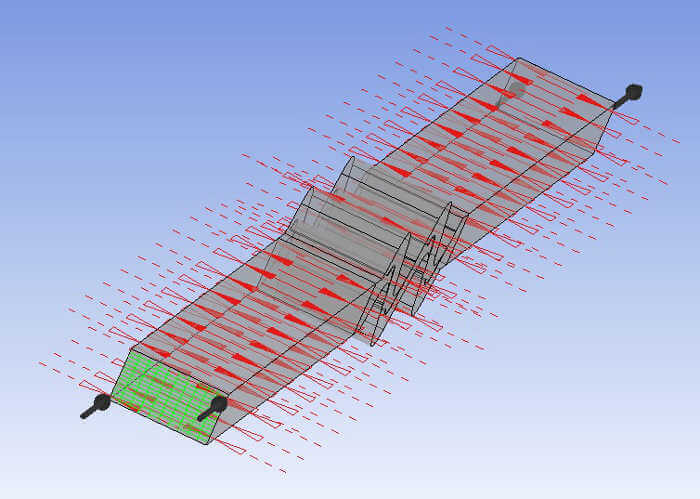

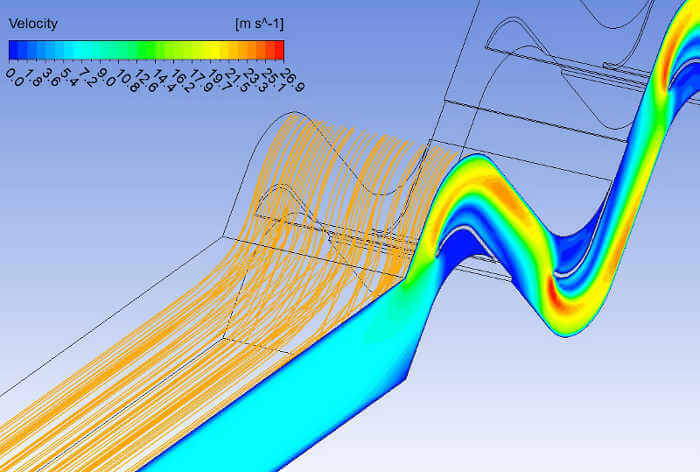

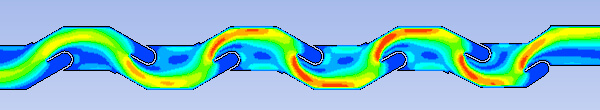

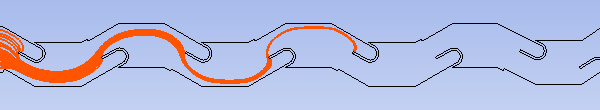

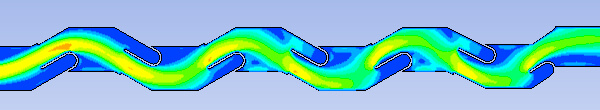

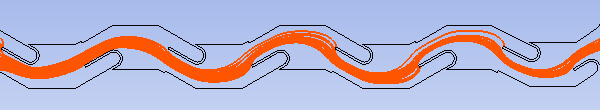

Nowadays, the simulation of the gas flow generated with a model is the best approach to the vane pack sizing. This method, studying the particle tracking and the behaviour of the flow, allows to check what actually happens inside the pack during the process.

It is thus possible to choose, customize and optimize the vane pack with a high degree of accuracy of the performances achieved and the reduction of dimensions and costs as well.

Samples of simulations using different vane profiles and conditions