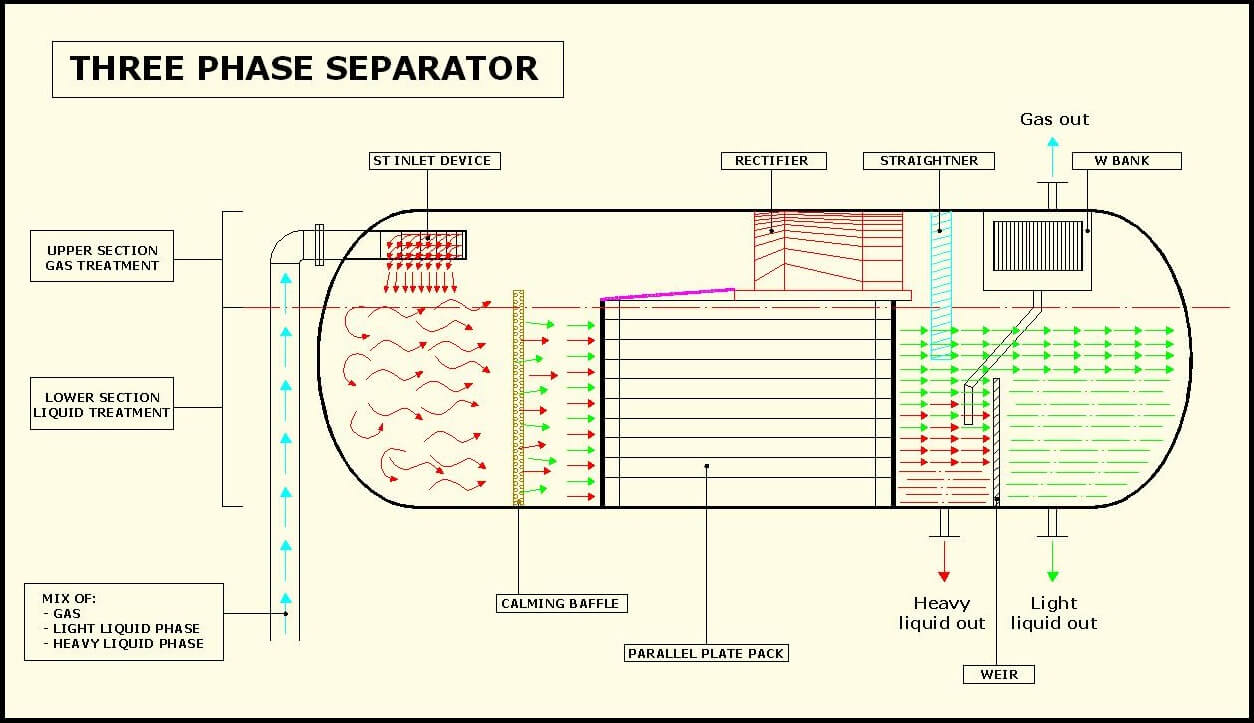

The three phases separation consists in the treatment of a flow composed of three different phases. Usually one of them is in aeriform state and the other two are in liquid state. So, in general, we have:

- gas phase: as for example methane, hydrocarbon gas, natural mixed gas;

- liquid light phase: for example oil;

- liquid heavy phase: for example water;

The three phases separation is used to achieve a gas flow without a high quantity of entrained liquid droplets and two separated flows of liquid light phase and liquid heavy phase.

PROCESS: In general a AFP ST inlet device is used to calm and distribute the flow at the inlet of a vessel and to obtain the separation of the liquid phases from the gas phase.

The flows are forced to pass through some internals at the same time but in two different sections of the vessel:

- the upper section where the gas flow is treated with, for example, a rectifier, a straightener and a vane pack.

- the lower section where the liquid flow is treated with, for example, a calming baffle, a plate pack coalescer and a weir

INTERNALS: the composition of the internal set can change according to the characteristics of the fluids and of the required performance. A sample of separator is the so-called "Gravity separator", where the only internal is usually a ST inlet device and the light liquid phase and the heavy liquid phase are roughly separated by the effect of gravity.

In other cases, special internals are required to meet the performance needed. For example:

- a double calming baffle instead of a simple one;

- a wire mesh coalescer instead of a parallel plate pack;

- a wire mesh separator instead of a vane pack;

SIZING: the sizing of a 3ph separator and of its internals is a complex process where different parameters are to be considered, as, for example:

- characteristics and properties of the fluids as density, viscosity, chemical composition, molecular weight etc.;

- required residence time in the vessel;

- required dimensions of the vessel based on location and other needs like, for example, existing piping;

- required process performances as, for example, the minimum diameter of the liquid droplets separated.