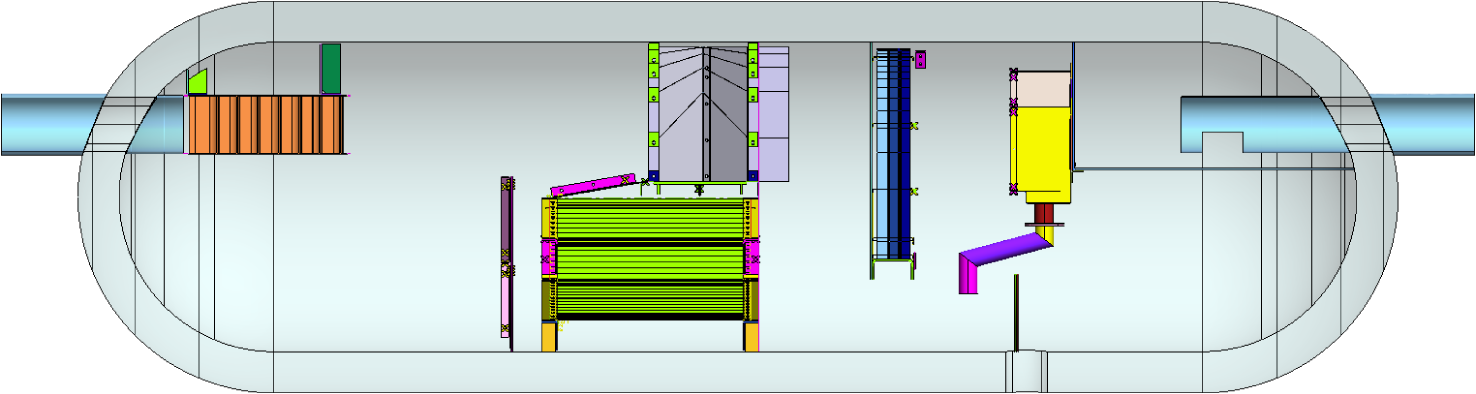

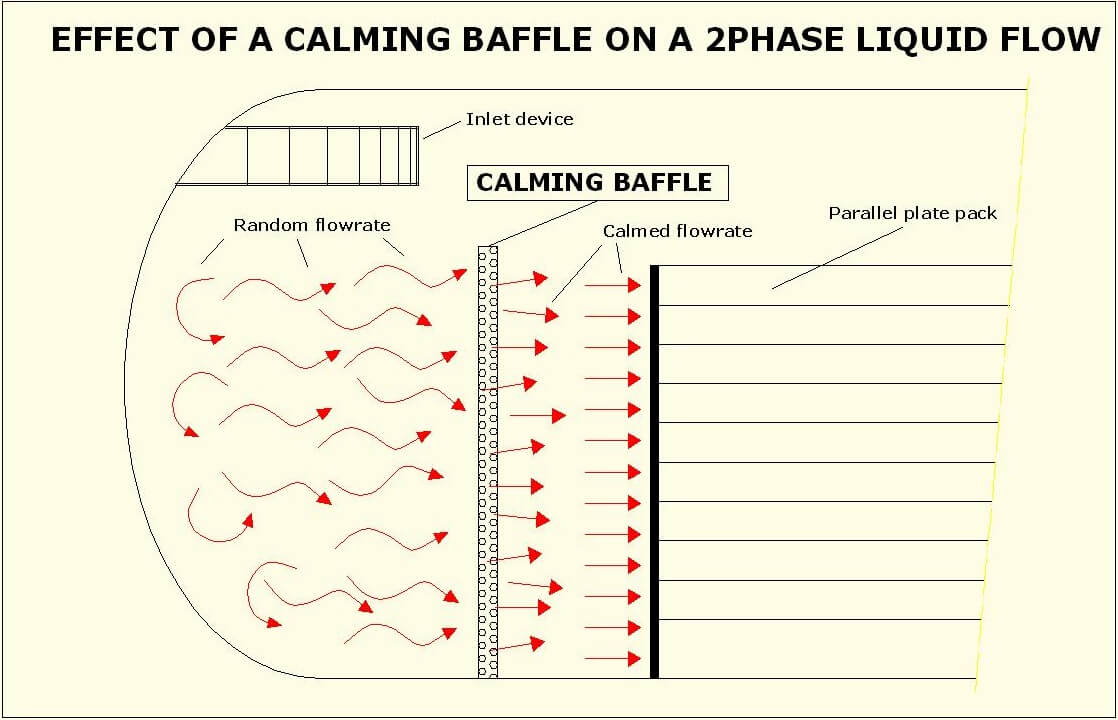

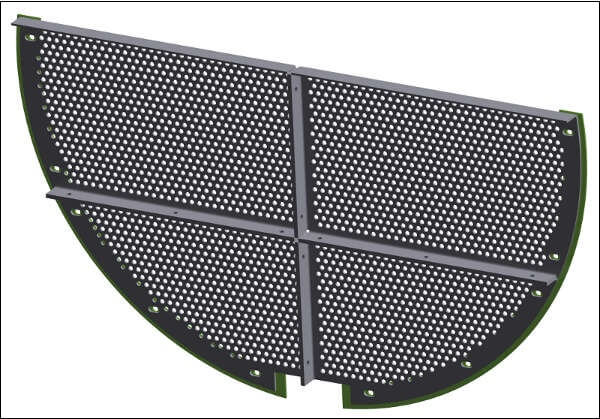

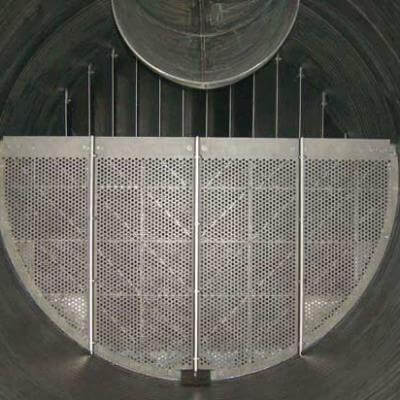

CALMING BAFFLES

A calming baffle is a particular kind of perforated plate commonly used to prevent and eliminate flow turbulences inside the treatment plants and to introduce the two-phase liquid flow in the settling compartment with a laminar flow regime, as in the picture above.

The calming process of the flow rate is very useful because it provides the best performances from the parallel plate pack located after the calming baffle: when the liquid flow enters with regular distribution and speed, the separation process can immediately start. Without a calming baffle, the liquid distribution can be very chaotic and the performance of the plate pack decreases consistently.

In some particular cases, it is possible to use a Double Calming Baffle usually made by two different calming baffles in series. This configuration significantly increases the calming effect on the flow but, on the other hand, requires more space and is more expensive.

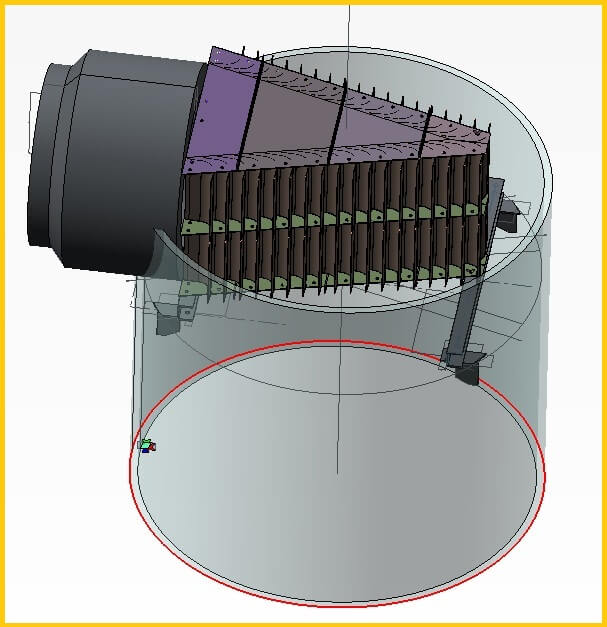

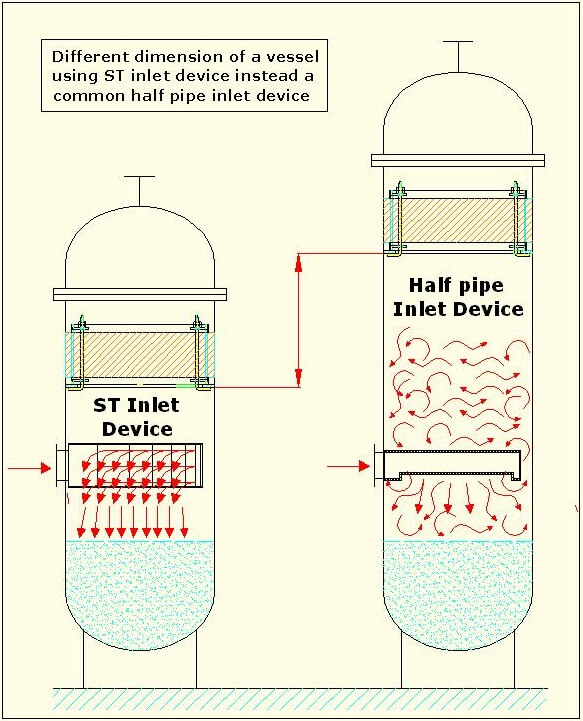

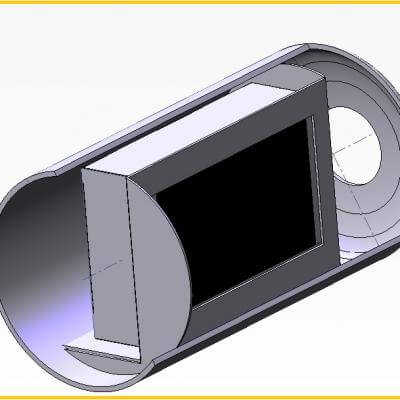

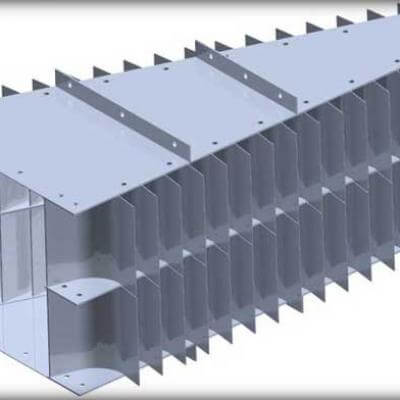

ST INLET DEVICE

The AFP tech ST inlet device is composed of one or more planes of vanes and two covers that allow the flow canalization through the slots in the vanes.

This inlet device is widely used in horizontal and vertical vessels with a high inlet flow, composed of a mix of liquid and gas

The two most important effects of the ST inlet device on the flow are:

- a first separation between the liquid and the gas phase.

- a regular and optimal distribution of the gas flow through the vessel

The main advantages provided by ST inlet devices are:

- reduction of the vessel dimensions with a significant saving of material, transport and installation costs.

- reduction of the diameter of the inlet nozzle

- reduction of the stress due to the flow